We have built slitter for a wide variety of materials, such as paper, cardboard, plastic film of all kinds, insulating and sealing material, bonded leather, thin sheet metal, highly elastic insulating materials or pressure-sensitive foils with supporting carrier paper as well as rubber and floor coverings.

Here are some reference objects:

-

Slitter with tangential cut

This slitter constellation ensures an edge-friendly cutting process decreasing material stress and is suited for a wide variety of materials (e.g. paper, plastic film, textiles, etc.). Equipped with a pneumatically expanding knife shaft for the bottom knifes and pneumatic top knife holder the slitting positions can be changed quick and easy.

This slitter constellation ensures an edge-friendly cutting process decreasing material stress and is suited for a wide variety of materials (e.g. paper, plastic film, textiles, etc.). Equipped with a pneumatically expanding knife shaft for the bottom knifes and pneumatic top knife holder the slitting positions can be changed quick and easy. Material: paper, cardboard, plastic films, textile

Working width: 1.850 mm -

Slitter for weighted film

With the "crush cut" method (crush cut knife on hardend surface) a wide variety of materials (e.g. weighted film, max. 6 mm thickness) can be cut easily.

Technical data of the machine displayed

Working width: 500 bis 2.000 mm -

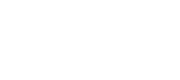

Rotary shear (slitter)

The rotary shear is used to slitt thick material webs (e.g. cardboard, leather, rubber, sponge cloth, etc.). The solid construction absorbs high forces that may occur during slitting. The double-split rotary knives allow a knife change without removing the knife shafts.

Technical data of the machine displayed:

Working width: 1.500 mm

-

Slitter system type LSA 4/25/1600

The rotary shear knifes slitt thin aluminum foil with minimal burr.

The rotary shear knifes slitt thin aluminum foil with minimal burr.

Working width: 40 bis 1.600 mm

Web thickness: 0,1 - 0,5 mm -

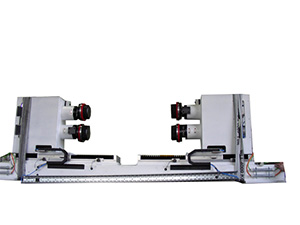

Trimming as exchangeable device

The trimming device is equipped with 2 saw units and is used to trim a stiff material web (e.g. laminate or chipboard, etc.). Depending on the material, this unit can be exchanged for a cassette with a different cutting system (e.g. with circular knives).

Technical data of the machine displayed

Working width: 500 - 1.450 mm Web thickness: 2 mm